Overcoming the Limitations of Traditional Timing Devices

A new approach to automotive timing, Chorus automotive clock generators integrate a MEMS resonator, oscillator, and advanced safety mechanisms into a single package. Hardware designers get the combined benefits of up to 10X higher performance in half the size compared to standalone oscillators, plus critical diagnostic coverage to achieve functional safety metrics more easily.

| Device | Datasheet | Number of Outputs | Serial Interface | Output Type |

Phase Jitter (RMS) | Output Frequency Range |

Size (QFN) |

|---|---|---|---|---|---|---|---|

| SiT91281 | 8 single-ended, 4 differential |

I2C or SPI | LVDS, FlexSwing, LPHCSL, LVPECL, HCSL, LVCMOS | 150 fs (typ) | 1 to 700 MHz (differential), 1 to 220 MHz (LVCMOS) |

4 x 4 mm | |

| SiT91283 | 8 single-ended, 4 differential |

I2C or SPI | LVDS, FlexSwing, LPHCSL, LVPECL, HCSL, LVCMOS | 70 fs (typ) | 1 to 700 MHz (differential), 1 to 220 MHz (LVCMOS) |

4 x 4 mm | |

| SiT91288 | 8 single-ended, 4 differential, PLL bypass |

I2C or SPI | LVDS, FlexSwing, LPHCSL, LVPECL, HCSL, LVCMOS | 150 fs (typ) | 1 to 700 MHz (differential), 1 to 220 MHz (LVCMOS) |

4 x 4 mm | |

| SiT91285 | 8 single-ended, 4 differential |

- | LVCMOS, HCSL, LPHCSL | 200 fs (typ) | 24, 25, 38.4, 40, 48, 50, 100, 125, or 156.25 MHz | 4 x 4 mm |

Chorus with FailSafe™ technology fulfills the timing needs of safety-critical systems such as ADAS/Infotainment, sensor, and gateway applications. These flexible clocks have configurable output frequency, output types, output skew control, and supply voltage, along with other programmable features to meet specific design requirements. Additionally, with an industry-first wide operating temperature range from -40°C to 125°C, Chorus is uniquely positioned to remove any thermal bottlenecks in the design of safety critical modules.

- Higher performance: Up to 10X better resilience with integrated MEMS resonator

-

Features to enable functional safety: Built-in programmable fault monitors

-

Design simplicity: Integrated MEMS technology speeds the design process and eliminates common issues such as noise and impedance matching

-

Smaller footprint: Up to half the size in a 4 mm x 4 mm QFN

-

Flexible frequency: Programmable frequency from 1 MHz to 700 MHz

-

Low RMS phase jitter: 70 fs typical (12 kHz to 20 MHz)

-

Excellent frequency stability: ±20 ppm (-40°C to 105°C) or ±50 ppm (-40°C to 125°C)

-

Flexible output types: Up to four differential (LVPECL, FlexSwing™, LVDS, HCSL, LPHCSL) or eight LVCMOS outputs

-

Reduced power and simplified circuitry: FlexSwing output reduces power consumption and eliminates termination resistors

-

Flexible supply voltage: Programmable, 1.8V, 2.5V, or 3.3V

-

EMI reduction: Configurable spread-spectrum, programmable rise/fall times

-

Compliant with the latest PCIe standard: Generation 1 to 6

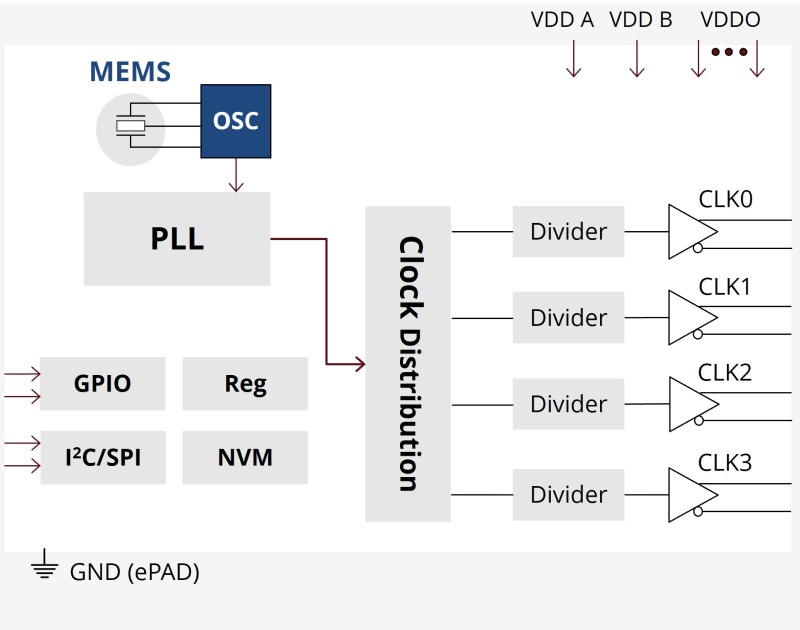

Fully Integrated Timing Solution

Chorus Automotive clock generators are a highly integrated, clock-system-on-a-chip (ClkSoC) that combines SiTime's latest-generation MEMS resonator with a low-noise PLL to deliver exceptional performance, reliability, and environmental resilience.

Chorus integrates multiple fully-programmable clock outputs, each with its own dedicated power supply. Non-volatile memory (NVM) stores a host of configurable parameters such as output frequency, programmable output skew control, and supply voltage, along with other programmable features to meet specific design requirements. On-chip regulators (Reg) provide extremely good power supply noise rejection. Additionally, FailSafe monitoring of multiple internal parameters is available through GPIO pins or direct access of internal registers via I2C/SPI interfaces.

This integrated approach eliminates quartz-related performance, reliability, and design issues, as well as simplifies system clock architecture, reduces BOM, and accelerates design time and safety analysis.

10X Lower Failure Rate

Quartz resonators are one of the most common sources of failures in safety critical automotive systems. Traditional clock devices require external quartz resonators as input clock references, exposing sensitive analog nodes to system noise and causing reliability, design, and performance issues. In contrast, Chorus automotive integrates a silicon MEMS resonator inside the clock, eliminating quartz reliability and sensitivity risks. The mass of MEMS resonators is up to 1000X smaller than quartz crystals. This gives them high shock and vibration survivability and makes them virtually immune to vibration-induced phase noise. MEMS-based clock generators are up to 10X more reliable and resilient.

50% Smaller Footprint

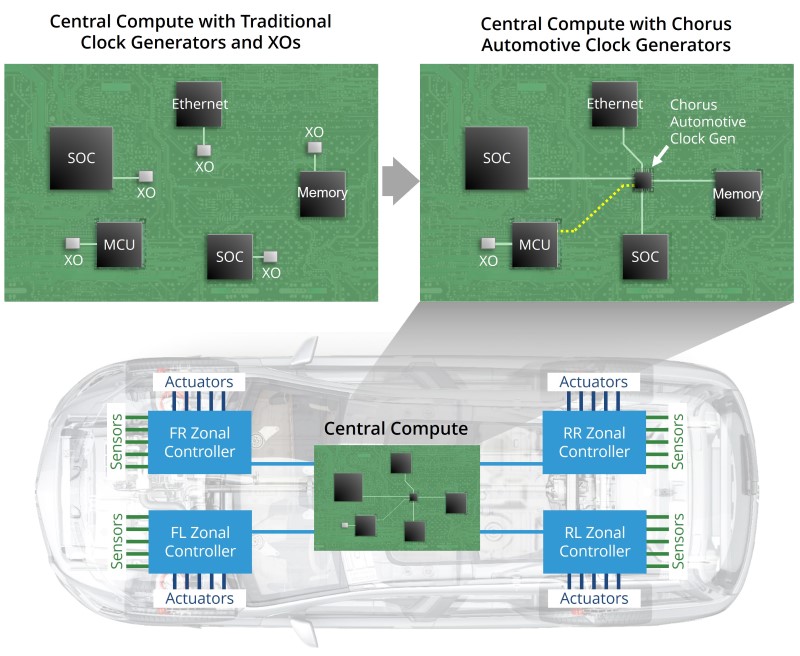

Board space is at a premium as automotive systems pack more functionality into smaller spaces. Chorus automotive is optimized for safety critical automotive systems with complex clock trees that require multiple reference clocks. Traditional clock devices depend on an external quartz crystal resonator (XO) or oscillator as an input reference for clock generation. In contrast, Chorus automotive clock generators incorporate an integrated MEMS resonator and can replace up to four XOs. Its compact 4 mm x 4 mm package can shrink the total clock tree footprint by up to 50%. Chorus automotive not only reduces board space, but with fewer components in the clock tree, it reduces clock failure rates and improves fault coverage.

This example shows how Chorus Automotive simplifies the ADAS ECU clock tree and can reduce board space.

A single Chorus clock handles the precision timing for ADAS compute SOCs and multiple high-speed interfaces.

1000X Faster to Safe State

In conventional clock trees, if the clock for an essential component fails, catastrophic failures can occur. A safety microcontroller in the system monitors such large-scale failures and will disable the failing function to reach a safe state. Time is of the essence to reaching safe state and reducing the fault-tolerant time interval (FTTI), or the time between a fault occurring and the system notification, is critical. Chorus automotive can shave off essential milliseconds by reporting clock faults before a downstream system-wide failure can occur.

Chorus automotive clocks incorporate SiTime’s FailSafe technology—an advanced end-to-end monitoring of the entire clock generation signal path. This is not possible when pairing an off-the-shelf quartz resonator with a traditional clock generators. With Chorus automotive, designers can choose the level of granularity with which they wish to monitor the clock (global monitor or sub-circuit level, selectively for one output or all outputs, etc.). They can choose to report clock failures to a safety microcontroller via immediate interrupt, or via a serial interface and periodic polling. Fault coverage and fault tolerant time interval can be tailored according to system level safety goals.

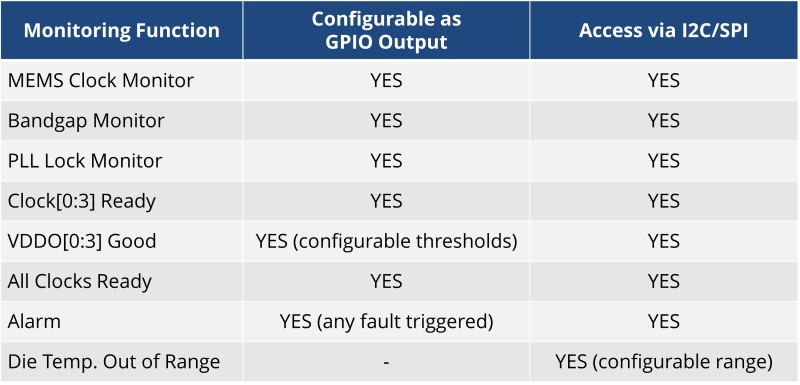

Chorus Automotive clock generator diagnostic and monitoring functions, configuration options, and serial interfaces.

Key Resources

Chorus Automotive Clock Generator FAQs

Chorus Automotive Evaluation Board

Chorus Automotive Enables High Levels of Safety with FailSafe Technology